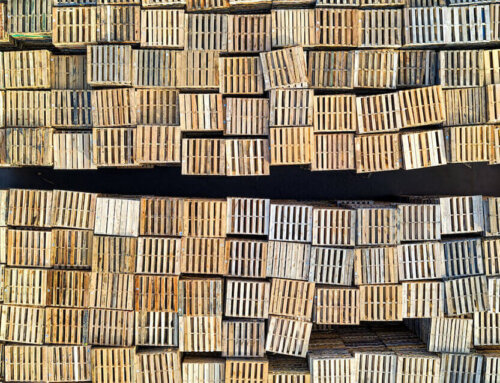

Pallets are an essential tool for any business that ships and stores products. If used inappropriately, pallets can be dangerous, causing injury to employees.

To ensure your employees stay safe, and your pallets undamaged, here are a few tips from your local pallet experts:

- Do not use rotting or damaged pallets. Damaged pallets can be extremely dangerous and can cause large columns of products to shift and even fall. This poses a risk to both your employees and products. Examine pallets for damage on a usual basis.

- Do not use pallets to lift employees. For this purpose, you should only use platforms properly engineered to lift employees. Some pallets are designed to hold over 4,000 pounds, but this weight is distributed evenly, unlike the feet of a human being.

- If you are manually moving a pallet, be wary of your body position. Pallets should be moved by forklifts or other machinery; however, there are certain instances when they must be moved by hand. Pallets can weigh upwards of 40 pounds and should be lifted with care. If done correctly, your back should be kept straight, and your legs should be doing most of the lifting.

- Enter pallets carefully with a forklift. When using a forklift or power jack, be sure to enter the load squarely, and be aware that when moving underneath the pallet, you may be pushing it forward, potentially into an employee or other products.

- As a rule, the height of a stack of pallets should not exceed the length of the bottom pallet (around four feet high.) Stacking pallets too high can result in product damage and injuring workers. Wrapping the load with shrink-wrap minimizes the possibility of accidents happening. Pallets should be stacked uniformly in a way that maximizes the strength of the individual pallets.

- Wear personal protective equipment (PPE.) Personal equipment like gloves, steel-toed boots, and high vis vests are important when working in an environment where pallets are handled regularly. Wearing PPE will avoid slips, trips, falls, and puncture wounds.

- Clean up any debris in your workspace. Debris left over from any broken or damaged pallets is dangerous for a number of reasons. Sharp wood and nails can puncture your employees and cause trips, slips, and falls. Keep a clean workspace to avoid any injury.

To keep your workers and products safe, it’s important to know how to properly handle your pallets. By keeping a clean workspace, ensuring proper personal protective equipment, and regularly inspecting your pallets, you can ensure your workers and products will stay unharmed.

At Pallet Management Group, we are committed to providing our clients with the high-quality recycled wood pallets they have come to expect from us. We also buy your used and broken wood pallets, so you can turn your old scraps into cash.

For more information about our recycled wood pallet products and services, contact us today at Pallet Management Group, or if you’re located in the Milton or London area, visit our sister company site, GLWP.

Leave A Comment

You must be logged in to post a comment.